TRAINING / CERTIFICATION PROGRAMME

Remmet offers training in various specialties in the oil & gas sector that are of international standards. Our course level ranges from Basic to Advanced, and they equip participants with good understanding and adequate exposure to the courses. Upon completion of our courses, our participants, mainly drawn from the Oil & Gas and Heavy Engineering Industry, will be exposed to the practical aspects of their trade. We equip participants with the know-how & techniques acceptable globally. We conduct assessments which will determine the competency of trainees in accordance with Industry Regulations & Standards. All our syllabus are up to date.

Our Courses –

Blasting

The Basic Blaster Training Course is designed to cover all critical information and to ensure that participants are prepared to take the test and become a blaster. One will require a blasters certification in addition to a blasters license. The Basic Training Course is a requirement for anyone wanting a blasters certification, and the training must be taken before you can take the certification test.

Water Jetting Operators

High-pressure water jetting is the use of high-speed streams of high-pressure water to cut through almost all solid materials and to clean various surfaces. Manual high-pressure water jetting can be hazardous to untrained or unskilled users. Remmet offers this training in the use of pure water or water with abrasives, cleaning chemicals or other additives at an operating pressure of between 10,000 to 25,000 psi (70 to 170 MPa) from a system that includes an engine, pump, water storage tank hose, specialized nozzle and other accessories.

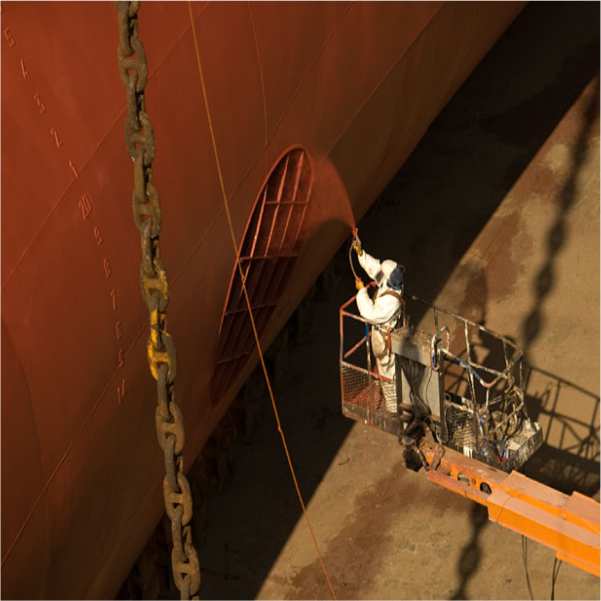

Painting

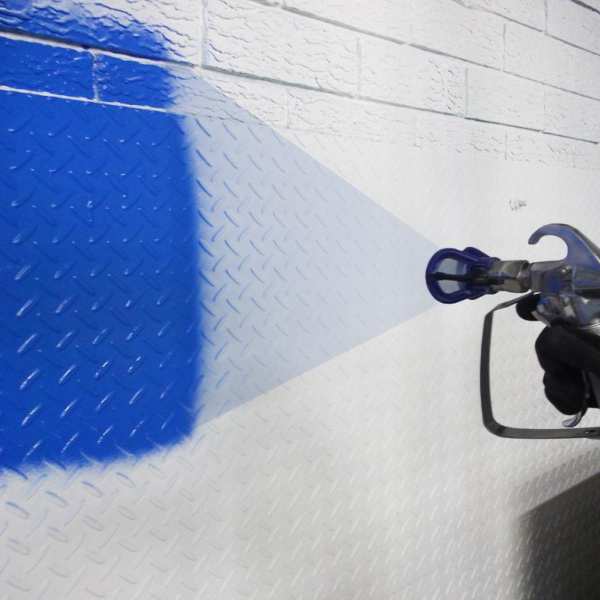

Remmet offers an internationally recognised and certified painting training programme. This course is designed for painters using protective coatings on industrial projects and hand applied coatings. It provides an introduction to anti-corrosion coatings and concrete water-proofing. The course is designed for professional painters who use protective coatings, are required to work to specification, or intend to work in the oil and gas industry.

Insulators

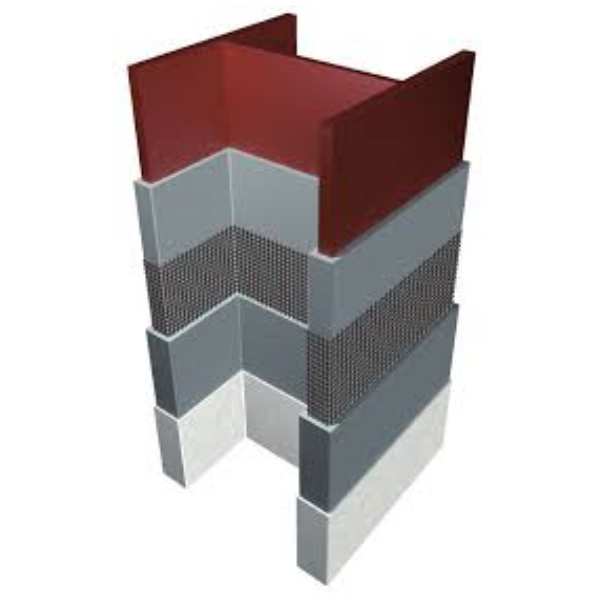

We train Insulators on the installation and replacement of the materials used to insulate buildings and their mechanical systems. They also handle insulation materials made of fiberglass, rubber, calcium silicate and urethane. The participants are taught how to remove asbestos containing materials.

At our training facility, participants are taught how to:

- Install plastic barriers to protect insulation from moisture.

- Measure and cut insulation to fit into walls and around pipes.

- Remove and dispose of old insulation.

- Secure insulation with staples, tape, or screws.

- Review blueprints and specifications to determine the amount and type of insulation needed.

- Use air compressors to spray foam insulation.

Our Training Portfolio –

Remmet is a fully accredited training provider for the oil and gas industry. We have successfully trained other providers in Nigeria. Our records speak volume of impacting our participants (individuals and corporate) with the require know-how to do their trade. The structure of our courses and study materials are based on acceptable industrial standards and accreditation in oilfield training. We are in constant touch with our esteemed clients to receive feedback from employers of labour to update our curriculum and exert adequate efforts towards developing contents that address practical aspects that are relevant to the industry.

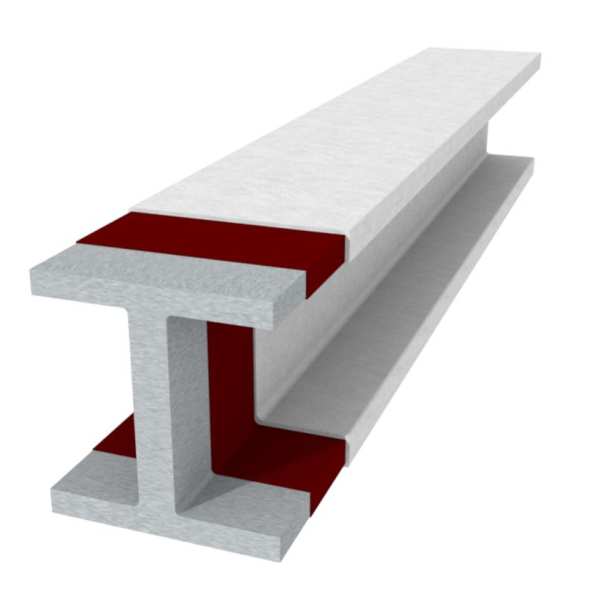

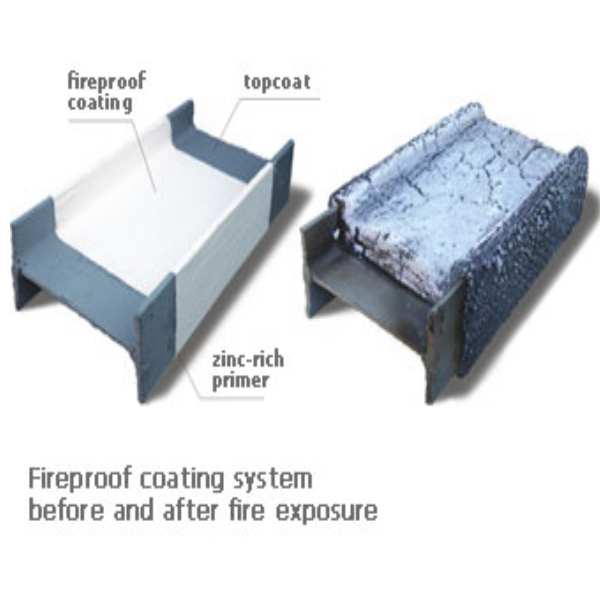

PFP Applicators

At Remmet, we train our participants on how to apply PFP coatings. This substance offers excellent thermal protection for the underlying surface when exposed to fire, even in an environment where hydrocarbons are present and there is a risk of a jet fire. These extremely strong epoxy coatings also offer excellent protection against the elements, solvents, acids, bases and alkalis, salts and obviously wear and tear at practically all temperatures. PFP coatings are used in many applications, such as steel structures (application both on-site and off-site using a brush or an airless spray system), oil refining, offshore oil platforms, the petrochemical industry and other high-risk industrial environments, offices, hospitals and other buildings.