CORROSION CONTROL SERVICES

At Remmet Services Nigeria Limited, our main goal for achieving optimal customer satisfaction is to evaluate environmental conditions, draw independent conclusions based on the data, and design a world-class corrosion control solution that provides long-term solutions to our customers corrosion -related issues. We can achieve this by identifying potential corrosion risks up front, our engineers can provide recommendations to minimize and/or eliminate corrosion risk in the most cost-effective manner.

Environmental Analysis

Remmet Corrosion engineers are experienced in analyzing and evaluating environmental factors that can result in corrosion, using such methods as soil surveys, site evaluations, stray current analysis, and water analysis. Corrosion mitigation strategies can be developed and implemented when the environmental analysis determines that corrosion risks are sufficient to warrant them.

Material Selection and Evaluation

Proper selection of materials is a critical component in minimizing corrosion risk. Based on the Environmental Analysis, our engineers can make material recommendations to minimize or eliminate corrosion. In addition, they will assess the potential interaction between dissimilar materials and make design recommendations to eliminate, minimize or negate the impact of dissimilar metals in a product or project design.

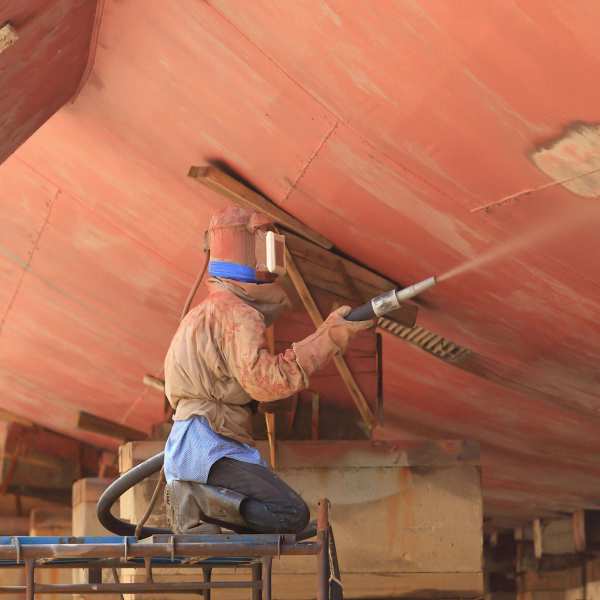

Coating Selection and Evaluation

The use of selective coatings is another important design element to minimize corrosion risk. Remmet Corrosion engineers can evaluate proposed coating materials and application procedures and/or make recommendations for the proper coating systems to optimize cost and effectiveness.

Soil and Water Testing

We have the resources to provide all required analytical services, ensuring compliance with federal, state, and local regulations. We have the resources to provide all required analytical services, ensuring compliance with federal, state, and local regulations. In addition, soil corrosion testing and monitoring services are provided in accordance to National Association of Corrosion Engineers (NACE) industry standards.

We have performed thousands of test samples for clients across the globe. The results of our data enable us to not only provide our clients the best recommendations to suit their needs but also adds to our best -practice data base allowing us to continue to build a world-class foundation for future corrosion designs.

- Chloride ion content

- Moisture content

- Presence of corrosion-activating bacteria

- Redox potential

- Resistivity

- Soil texture, internal drainage characteristics

- Sulfate ion content

- Oxygen content

- Permeability

- pH

- Total hardness as CaCO 3 of soil moisture

- Total acidity

Soil Corrosion testing is available for:

- Water

- Concrete

- Steel

- Cast/Ductile Iron

- Mortar Coated Steel

- Copper Piping

Upon completion of testing, a Remmet qualified corrosion engineer will provide you with a written report detailing conclusions and recommendations for your specific corrosion concerns.