CORROSION CONDITION ASSESSMENT

Remmet Services Nigeria Limited always strives to identify her clients’ pertinent needs at the get-go of every project with a view to minimise interruptions of their own services. We have also developed an ideal for the execution of condition assessments without posing any impediments to the progression of our customers’ services.

Our procedures for this process are captured below. We undergo:

Stage 1. a research into the infrastructure’s history with a view to acquire data like: how old is the pipeline; of what material is it; what is are the various alignments; are there records of past failure; what is the location’s proximity to stray current sources; corrosion control details (if any), etc.

Stage 2. a Non-Destructive Inspection. From our vault of experience, our choices of non-destructive inspection methods are many. For instance; we could carry out stray current analysis, soil resistivity measurements, soil sampling, cell to cell survey as well as close interval survey. All the data obtained from this stage of work will be analyzed, correlated, and interpreted by our senior corrosion engineering staff.

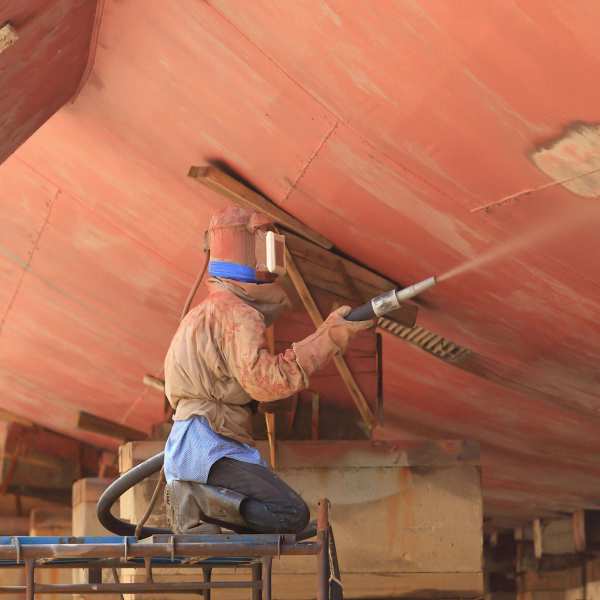

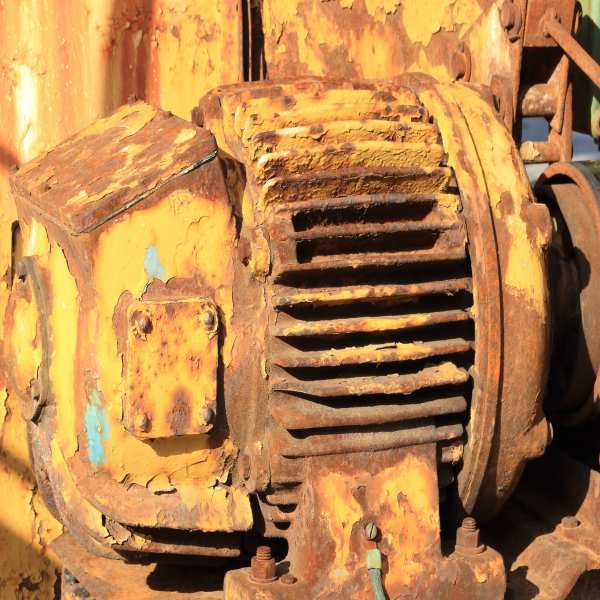

Stage 3. a Direct Pipeline Inspection. This is based on the evaluation of results from stage 1 and 2 above. Our team will subsequently determine the exact location to perform direct test site inspections. Remmet engineers will outline the exact direct examination site where active corrosion is occurring on the customer’s asset, thus ensuring a true condition of the asset is determined. Once on proposed site, Remmet engineers will perform a thorough corrosion and condition assessment analysis, including; visual inspection, ultrasonic thickness measurements, corrosion rate measurements to determine how fast the asset is corroding, and additional soil sampling. All evaluations can be performed while the asset remains in service and while our staff is in the test site (subject to client’s preference).

Stage 4. a Final Evaluation Report and Analysis. Once Stage 3 is fully executed, all data is compiled and forwarded to Remmet Lab for finalizing the condition assessment report. A customer will receive a condition assessment report, a remaining asset lifecycle prediction, and any recommendations for refurbishment or replacement and future corrosion control solutions.

From the above outlined stages, we wish to assure our customers that their infrastructures’ condition can be assessed at an affordable rate as compared to the cost of achieving same results from leading technologies. Additionally, they can be take solace in the fact that they get an actual condition assessment of their asset while remaining cost conscious.